Self-Healing Materials: The Future of Sustainable Tech

Imagine a world where materials can mend themselves, just like our bodies heal after a cut. Self-healing materials are not just a figment of science fiction; they are becoming a reality and paving the way for a more sustainable future. These innovative materials possess the remarkable ability to autonomously repair damage, which significantly extends their lifespan and reduces waste. In an age where sustainability is paramount, the emergence of self-healing materials could revolutionize various industries, from construction to electronics.

The science behind these materials is fascinating. They are designed with unique properties that allow them to respond to damage in real-time. For instance, when a self-healing polymer gets scratched or cracked, it can release healing agents that bond the material back together. This process not only restores the material’s integrity but also minimizes the need for replacement and repair, saving resources and energy in the long run.

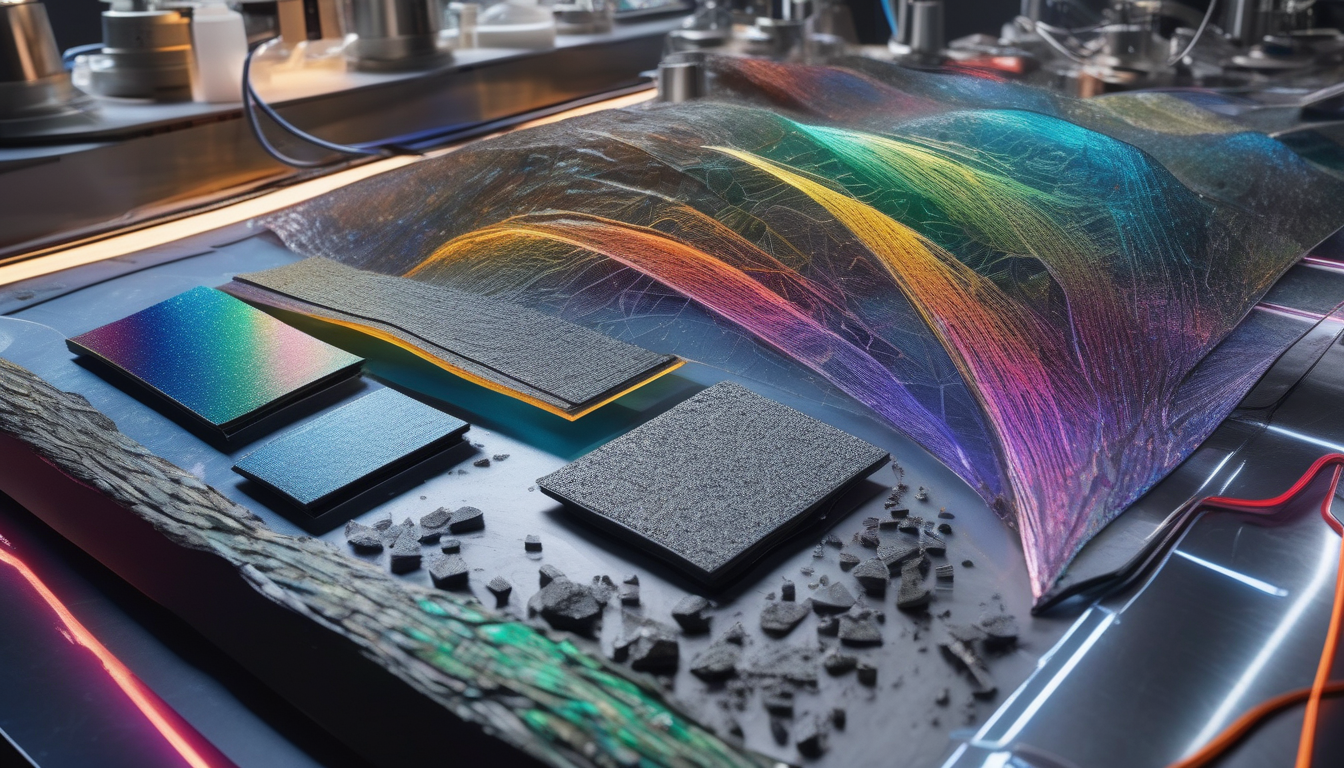

As we delve deeper into the types of self-healing materials, we find that they can be broadly categorized into polymers, metals, and ceramics. Each type has its own mechanisms for healing, making them suitable for various applications. For example, polymeric self-healing materials often utilize microcapsules that release healing agents upon damage. In contrast, metallic and ceramic materials may rely on phase transformations or chemical reactions to achieve self-repair.

The potential applications of self-healing materials are vast and varied. In construction, self-healing concrete can autonomously repair cracks, enhancing the durability of structures and reducing maintenance costs. In the electronics sector, these materials can improve device longevity, making smartphones and wearables more resilient to everyday wear and tear. By integrating self-healing technologies, we can transform industry practices and promote a more sustainable approach to manufacturing.

Ultimately, the environmental benefits of self-healing materials cannot be overstated. By reducing waste and resource consumption, they contribute significantly to a circular economy. As we embrace these innovative solutions, we move closer to a future where sustainability is not just an option but a standard. The journey towards a more sustainable world is filled with exciting possibilities, and self-healing materials are at the forefront of this revolution.

What Are Self-Healing Materials?

Self-healing materials are revolutionary substances designed to autonomously repair themselves after sustaining damage. Imagine a world where your smartphone screen could fix itself after a drop or where cracks in concrete could disappear without human intervention. This innovative technology extends the lifespan of products, drastically reduces waste, and promotes sustainability. The science behind these materials is fascinating, as they incorporate unique properties that allow them to sense damage and respond accordingly.

At their core, self-healing materials utilize various mechanisms to achieve repair. These mechanisms can be broadly classified into two categories: passive and active healing. Passive healing occurs without external intervention, often through embedded healing agents that are released when damage occurs. Active healing, on the other hand, involves a more complex interaction, where the material actively responds to damage by initiating a repair process.

Self-healing materials can be found in several forms, including:

- Polymers: These are the most common type, often used in coatings and flexible electronics.

- Metals: Certain metallic materials can undergo phase transformations to heal themselves.

- Ceramics: These materials often rely on chemical reactions to facilitate self-repair.

Understanding the properties and mechanisms of self-healing materials is crucial for their application in various industries. For instance, in construction, self-healing concrete can autonomously mend cracks, significantly enhancing the durability of structures. In electronics, self-healing polymers can lead to longer-lasting devices, reducing the need for repairs and replacements.

As we delve deeper into the world of self-healing materials, we uncover their potential to transform not only products but entire industries. The ability to self-repair not only saves money but also contributes to a more sustainable future by minimizing waste and resource consumption. In the next sections, we will explore the different types of self-healing materials and their practical applications across various sectors.

Types of Self-Healing Materials

When we dive into the fascinating world of self-healing materials, it’s like opening a treasure chest filled with innovative solutions designed to revolutionize our approach to durability and sustainability. These materials can be broadly categorized into three main types: polymeric, metallic, and ceramic. Each type boasts unique mechanisms that enable them to autonomously repair damage, making them essential in various applications. Let’s unpack each of these categories and explore their remarkable properties.

First up are polymeric self-healing materials, which are often at the forefront of this technology. They utilize sophisticated systems such as microcapsules or vascular networks to facilitate healing. Imagine a band-aid that automatically applies itself whenever you get a cut; that’s the essence of polymeric self-healing materials! These materials are particularly useful in coatings, adhesives, and flexible electronics, where maintaining integrity is crucial.

Next, we have metallic and ceramic self-healing materials. These materials often heal through phase transformations or chemical reactions, which can be likened to a phoenix rising from the ashes. They are designed to withstand extreme conditions while maintaining their structural integrity. For instance, certain metallic alloys can undergo transformations that allow them to ‘heal’ cracks or defects, making them ideal for high-stress applications.

To give you a clearer picture, here’s a quick comparison table highlighting the key features of each type:

| Type | Mechanism | Applications |

|---|---|---|

| Polymeric | Microcapsules, Vascular Networks | Coatings, Adhesives, Flexible Electronics |

| Metallic | Phase Transformation, Chemical Reactions | Aerospace, Automotive, Structural Components |

| Ceramic | Self-Healing through Phase Change | High-Temperature Applications, Electronics |

In summary, the diverse types of self-healing materials not only showcase the ingenuity of modern science but also pave the way for sustainable practices across various industries. As these materials continue to evolve, they hold the potential to significantly reduce waste and enhance the longevity of products we rely on every day.

Polymeric Self-Healing Materials

Polymeric self-healing materials are truly fascinating innovations that harness the power of chemistry to mimic the natural healing processes we see in living organisms. Imagine a world where your smartphone case or the coating on your car can magically repair itself after a scratch or a dent! This is not just a fantasy; it’s becoming a reality thanks to these remarkable materials.

At the heart of polymeric self-healing materials are two primary mechanisms: microcapsules and vascular networks. Each of these systems plays a crucial role in enabling the material to autonomously heal when damaged. For instance, microcapsule-based systems contain tiny capsules filled with healing agents. When the material experiences a crack or scratch, these capsules break open, releasing their contents to fill the damaged area and bond the material back together. This process not only restores the material’s integrity but also extends its lifespan, making it a game changer in various applications.

On the other hand, vascular network systems take inspiration from biological systems, much like the way our own circulatory system works. These materials are designed with channels that transport healing agents to the site of damage. When a crack occurs, the healing agents flow through these networks, effectively sealing the damage and preventing further deterioration. This method is particularly effective in large structures, such as buildings and bridges, where maintaining integrity is crucial.

The applications of polymeric self-healing materials are vast and varied. They are being used in:

- Coatings: Protecting surfaces from scratches and wear.

- Adhesives: Creating stronger bonds that can repair themselves.

- Flexible Electronics: Enhancing durability in devices that bend and flex.

With such a wide range of applications, polymeric self-healing materials are not just a technological novelty; they represent a significant step toward sustainability. By reducing the need for replacements and repairs, these materials contribute to a more circular economy, ultimately benefiting both manufacturers and consumers alike. As we continue to innovate and improve these materials, we can look forward to a future where self-healing technology becomes the norm, rather than the exception.

Microcapsule-Based Healing

Microcapsule-based healing is a fascinating technology that allows materials to repair themselves when damaged. Imagine a scratch on your favorite car that magically disappears—this is the essence of microcapsule healing. These materials contain tiny capsules filled with a healing agent, which are embedded within the material. When a crack or scratch occurs, these microcapsules break open, releasing the healing agent to fill the gap and bond the material back together.

One of the most exciting aspects of microcapsule-based healing is its versatility. This technology can be used in a variety of applications, from coatings that protect surfaces to adhesives that hold components together. For instance, in the realm of construction, self-healing concrete utilizes microcapsules filled with a special polymer. When cracks form in the concrete, the capsules rupture, and the polymer flows into the crack, solidifying and restoring the integrity of the structure.

Here are some key benefits of microcapsule-based healing:

- Cost-Effective: By extending the lifespan of materials, these systems reduce the need for repairs and replacements, saving money in the long run.

- Enhanced Safety: In critical applications, such as aerospace and automotive industries, self-healing materials can prevent catastrophic failures by maintaining structural integrity.

- Environmental Impact: Fewer repairs and replacements mean less waste, contributing to a more sustainable future.

Moreover, the technology is constantly evolving. Researchers are exploring new types of healing agents and microcapsule designs to improve the efficiency and effectiveness of these materials. For example, some innovative approaches involve using bio-based healing agents that are environmentally friendly, further enhancing the sustainability aspect of this technology.

In conclusion, microcapsule-based healing represents a significant leap forward in material science. As we continue to innovate and refine this technology, we can expect to see even more applications across various industries, leading to safer, more durable, and sustainable products that can withstand the test of time.

Vascular Network Systems

Imagine a world where materials can heal themselves, much like how our bodies recover from injuries. are at the forefront of this innovation, mimicking biological processes to transport healing agents directly to damaged areas. This technology operates on the principle of a circulatory system, where pathways are designed to deliver necessary components for repair, ensuring that materials can autonomously mend themselves after sustaining damage.

The design of these systems is both intricate and fascinating. Typically, vascular networks are embedded within a material, creating a web-like structure that allows for efficient distribution of healing agents. When a crack or fracture occurs, a triggering mechanism activates the release of these agents, which then flow through the network to the affected area. This process not only restores the material’s integrity but also enhances its overall lifespan.

One of the most compelling aspects of vascular network systems is their application across various industries. For instance, in the construction sector, self-healing concrete equipped with vascular networks can autonomously repair cracks, significantly improving structural durability. Similarly, in the automotive industry, these materials can be used in components that are prone to wear and tear, ensuring that vehicles remain safe and reliable over time.

Moreover, the effectiveness of vascular network systems can be illustrated in a simple table:

| Industry | Application | Benefits |

|---|---|---|

| Construction | Self-healing concrete | Enhanced durability, reduced maintenance costs |

| Automotive | Wearable components | Increased safety, prolonged lifespan |

| Electronics | Flexible devices | Improved longevity, reduced waste |

In summary, vascular network systems represent a significant leap forward in the realm of self-healing materials. By integrating these networks into various products, we can not only enhance their performance but also contribute to a more sustainable future. The potential for these systems is vast, and as technology advances, we can expect to see even more innovative applications emerge.

Metallic and Ceramic Self-Healing Materials

When you think about self-healing materials, you might picture flexible polymers or coatings that magically fix themselves. But hold on! are stepping into the spotlight, bringing their unique characteristics and innovative mechanisms to the table. These materials are not just tough; they have a knack for repairing themselves through fascinating processes like phase transformation and chemical reactions.

Imagine a car that can fix its own dents or a bridge that can seal its own cracks. That’s the promise of metallic and ceramic self-healing materials! These materials often utilize intrinsic properties that allow them to respond to damage in real-time. For instance, certain metals can undergo a phase change when stressed, allowing them to return to their original state. This is akin to a shape-shifting superhero who can adapt to challenges and come back stronger!

In ceramics, the self-healing process often involves chemical reactions that can occur when the material is exposed to heat or moisture. This means that a ceramic tile, for example, can mend itself over time, significantly extending its lifespan. The combination of these properties not only enhances the durability of the materials but also reduces the need for replacements, which is a big win for sustainability.

Let’s take a closer look at the characteristics of these materials:

| Material Type | Self-Healing Mechanism | Applications |

|---|---|---|

| Metallic | Phase Transformation | Aerospace, Automotive |

| Ceramic | Chemical Reaction | Construction, Electronics |

The potential applications of these materials are vast and varied. In the aerospace industry, for instance, metallic self-healing materials can enhance the safety and longevity of aircraft components. Similarly, ceramic self-healing materials can revolutionize construction, making buildings more resilient to environmental stressors. The future is looking bright with these innovative materials paving the way for a more sustainable and efficient world!

Applications in Various Industries

Self-healing materials are not just a fascinating concept; they have practical applications that are transforming various industries. Imagine a world where buildings can repair themselves, or your smartphone can withstand the wear and tear of daily life without a hitch. These innovative materials are paving the way for a future where sustainability and efficiency go hand in hand.

In the construction sector, self-healing concrete is a game changer. This revolutionary material can autonomously seal cracks as they form, significantly enhancing the durability of structures. For instance, when a crack appears, embedded capsules containing healing agents are released, filling the void and restoring the integrity of the concrete. This not only extends the lifespan of buildings but also reduces the need for costly repairs and maintenance. The implications for infrastructure sustainability are enormous, as this technology can lead to less material waste and lower resource consumption.

Moving on to the electronics industry, self-healing materials are making waves in consumer products. Think about your favorite gadgets—smartphones, tablets, and wearables. With self-healing polymers, these devices can recover from minor scratches and dents, maintaining their aesthetic appeal and functionality. This capability not only enhances user experience but also contributes to longer product lifespans, reducing electronic waste. As technology continues to evolve, the integration of self-healing materials in everyday items is likely to become the norm rather than the exception.

Moreover, the healthcare sector is also reaping the benefits of these materials. Self-healing polymers are being explored for use in medical devices, where they can autonomously repair damage, ensuring that devices remain safe and effective over time. This is crucial in applications like prosthetics and implants, where durability and reliability are paramount.

In summary, self-healing materials are revolutionizing multiple industries by enhancing durability, reducing waste, and improving overall efficiency. As we continue to explore their potential, it’s clear that these materials are set to play a pivotal role in the future of sustainable technology.

Construction and Civil Engineering

In the realm of , self-healing materials are nothing short of a game-changer. Imagine a world where concrete cracks repair themselves, eliminating the need for constant maintenance and reducing costs. This is not just a dream; it’s becoming a reality thanks to innovative technologies that harness the power of self-healing materials. These materials are engineered to respond to damage autonomously, effectively extending the lifespan of structures and enhancing their durability.

One of the most exciting applications is in the development of self-healing concrete. This specialized concrete incorporates healing agents, such as bacteria or polymeric microcapsules, that activate when cracks form. When a crack appears, these agents are released, filling the gap and restoring the material’s integrity. This not only enhances the structural performance but also significantly reduces the need for repairs over time, leading to substantial cost savings for construction companies.

Furthermore, the implementation of self-healing materials in infrastructure projects can lead to a more sustainable approach to construction. By minimizing the frequency of repairs, we can reduce the consumption of resources and the environmental impact associated with traditional construction practices. The table below illustrates some key benefits of using self-healing materials in construction:

| Benefit | Description |

|---|---|

| Cost Efficiency | Reduces maintenance and repair costs over the lifespan of the structure. |

| Durability | Enhances the longevity of materials, leading to fewer replacements. |

| Sustainability | Decreases resource consumption and waste generation. |

| Safety | Improves structural integrity, reducing the risk of failure. |

As we look toward the future, the integration of self-healing materials in construction will likely become a standard practice. Not only do they offer practical benefits, but they also align with the growing demand for sustainable building solutions. The construction industry is on the brink of a transformation, and self-healing materials are leading the charge toward a more resilient and eco-friendly future.

Electronics and Consumer Products

Have you ever dropped your smartphone and cringed at the thought of a shattered screen? Self-healing materials are here to save the day! These innovative materials are revolutionizing the electronics industry by enhancing device longevity and overall performance. Imagine a world where your gadgets can automatically repair themselves from minor scratches and dents, just like how our skin heals from cuts. This technology is not just a fantasy anymore; it’s becoming a reality!

In the realm of consumer products, self-healing materials offer a plethora of benefits. For instance, consider the flexibility and durability they bring to wearable technology. With the integration of these materials, wearables can withstand the rigors of daily life while maintaining their aesthetic appeal. Whether it’s a fitness tracker that can endure your intense workout sessions or a smartwatch that can survive accidental drops, self-healing materials are setting new standards for resilience.

Moreover, the incorporation of self-healing materials in electronics can lead to significant cost savings. By reducing the frequency of repairs and replacements, manufacturers can lower production costs and pass those savings onto consumers. This not only enhances the consumer experience but also contributes to a more sustainable approach to electronics manufacturing. With less waste generated from discarded devices, we’re taking a step closer to a circular economy.

To illustrate the impact of self-healing materials in electronics, consider the following table:

| Device Type | Self-Healing Feature | Benefits |

|---|---|---|

| Smartphones | Scratch-resistant screens | Improved durability and aesthetic longevity |

| Wearable Devices | Flexible, self-repairing bands | Enhanced comfort and reduced replacement costs |

| Laptops | Self-healing casings | Protection against minor impacts and scratches |

As we continue to embrace these self-healing technologies, the future of electronics and consumer products looks promising. With the potential to transform how we interact with our devices, self-healing materials are not just a trend; they are paving the way for a more sustainable and resilient technological landscape.

Environmental Benefits of Self-Healing Materials

When we think about the future of technology, self-healing materials stand out as a beacon of hope for sustainability. These innovative materials not only promise to revolutionize various industries but also play a crucial role in protecting our planet. By reducing waste and minimizing resource consumption, self-healing materials are paving the way for a more sustainable future.

One of the most significant environmental benefits of self-healing materials is their ability to prolong the lifespan of products. Imagine a world where your smartphone or favorite gadget doesn’t need to be replaced every couple of years. With self-healing capabilities, these materials can effectively repair minor damages, significantly decreasing the frequency of replacements. This not only saves consumers money but also reduces the amount of electronic waste that ends up in landfills.

Moreover, self-healing materials contribute to a circular economy. By extending the life of products, we can shift from a linear model of consumption—where we take, make, and dispose—to a more sustainable approach. This means that instead of constantly extracting new resources to create new products, we can reuse and repair existing ones. This shift can lead to substantial reductions in the environmental footprint of manufacturing processes.

To illustrate the impact of self-healing materials on waste reduction, consider the following:

| Aspect | Traditional Materials | Self-Healing Materials |

|---|---|---|

| Product Lifespan | Shorter | Longer |

| Frequency of Replacement | High | Low |

| Waste Generation | High | Reduced |

Additionally, self-healing materials enhance energy efficiency throughout their lifecycle. By minimizing the need for repairs and replacements, they significantly lower the energy consumption associated with manufacturing new products. This not only conserves resources but also reduces greenhouse gas emissions, making our planet a cleaner and healthier place to live.

In summary, the environmental benefits of self-healing materials are profound. They not only reduce waste and promote sustainability but also encourage a shift towards a more responsible way of consuming and producing. As we continue to innovate in this field, the potential for a greener future becomes increasingly tangible.

Waste Reduction and Longevity

In today’s world, where environmental concerns are at an all-time high, waste reduction has become a crucial focus for industries worldwide. One of the most exciting advancements in this arena is the development of self-healing materials. These innovative materials not only promise to enhance product durability but also significantly reduce waste generated from damaged goods. Imagine a world where your smartphone or car could “heal” itself from minor damages—sounds like science fiction, right? But it’s becoming a reality!

Self-healing materials extend the lifespan of products by autonomously repairing damage, which translates to fewer replacements and less waste. This is particularly vital in sectors like construction, where materials like concrete can develop cracks over time. With self-healing concrete, these cracks can be repaired automatically, ensuring the structure remains sound without the need for extensive repairs. This feature not only saves time and money but also reduces the amount of concrete waste that would otherwise end up in landfills.

Consider the following statistics that highlight the potential impact of self-healing materials on waste reduction:

| Sector | Traditional Waste Generation | Potential Waste Reduction with Self-Healing Materials |

|---|---|---|

| Construction | 30% of materials wasted | Up to 50% reduction |

| Electronics | 20 million tons of e-waste annually | 30% less e-waste |

Not only do these materials reduce waste, but they also promote a more sustainable approach to manufacturing. By utilizing self-healing technologies, manufacturers can produce items that last longer, thereby conserving resources that would otherwise be used for repairs or replacements. This shift towards longevity is essential for fostering a circular economy, where products are designed to be reused and recycled rather than discarded.

In summary, the integration of self-healing materials into various industries represents a significant leap towards sustainability. By minimizing waste and prolonging product lifespan, these materials are not just a technological marvel; they are a vital step towards a greener future. It’s time to embrace this innovation and pave the way for a more sustainable world!

Energy Efficiency and Resource Conservation

When we talk about self-healing materials, we’re not just discussing a cool new technology; we’re diving into a realm that could reshape our approach to energy efficiency and resource conservation. Imagine a world where products last significantly longer, reducing the need for constant replacements. Sounds like a dream, right? But it’s becoming a reality thanks to these innovative materials.

Self-healing materials have the remarkable ability to autonomously repair themselves when damaged. This means that instead of tossing a broken item into the landfill, you can simply let it heal. This self-repair capability can lead to a dramatic decrease in waste, which is crucial in a world where we are constantly battling against resource depletion and environmental degradation.

To put it simply, the longer a product lasts, the less frequently it needs to be replaced. This directly translates into fewer resources being consumed over time. For instance, consider the impact of using self-healing concrete in construction. Not only does it extend the life of structures, but it also reduces the energy and materials required for repairs and replacements. The table below illustrates the potential energy savings and resource conservation achieved through self-healing technologies:

| Material Type | Energy Savings (%) | Resource Conservation (%) |

|---|---|---|

| Self-Healing Concrete | 30 | 40 |

| Polymeric Coatings | 25 | 35 |

| Flexible Electronics | 20 | 30 |

Furthermore, self-healing materials can enhance energy efficiency throughout their lifecycle. By minimizing the need for repairs and replacements, they reduce the energy required in manufacturing new products. This energy efficiency is not just beneficial for the environment; it also translates into cost savings for consumers and businesses alike.

In essence, self-healing materials pave the way for a more sustainable future. They embody the principles of a circular economy, where products are designed to last and reduce waste, ultimately conserving our planet’s precious resources. So, the next time you consider the lifecycle of a product, think about how self-healing materials could change the game for energy efficiency and resource conservation.

Frequently Asked Questions

- What are self-healing materials?

Self-healing materials are innovative substances designed to autonomously repair damage. They can significantly extend the lifespan of products and reduce waste, making them a game-changer in sustainable technology.

- How do self-healing materials work?

These materials typically utilize mechanisms like microcapsules or vascular networks to release healing agents when damaged. This allows them to fix themselves without external intervention, similar to how our skin heals from cuts.

- What are some examples of self-healing materials?

Common examples include polymeric materials used in coatings and adhesives, as well as metals and ceramics that can self-repair through chemical reactions. Each type has unique applications across various industries.

- What industries benefit from self-healing materials?

Self-healing materials have vast applications in industries such as construction, where they can enhance the durability of concrete, and electronics, where they improve the longevity of devices like smartphones and wearables.

- How do self-healing materials contribute to sustainability?

By reducing the need for repairs and replacements, self-healing materials help lower waste and resource consumption. This not only conserves materials but also promotes a circular economy by extending product life cycles.

- Are self-healing materials cost-effective?

While the initial investment might be higher, the long-term savings from reduced maintenance and extended product life often outweigh these costs, making them a smart choice for many industries.

The AI regulation and compliance section is spot on. With the rise of AI adoption, ethical considerations will be crucial.…